Slow economic periods are a time for reflection for many companies. Understanding how to react to an economic downturn is one of the hardest tasks for a manager. The focus must be on accomplishing more with less and reducing inefficiencies. How can you provide more services per person, lower administrative costs and reduce expenses while at the same time providing quality work and good customer services? This article is intended to help the reader start the process of self-evaluation - to explore where inefficiencies may be lurking in your own unique business environment.

The use of PDAs, Handhelds and other mobile software technologies, in the context of field services automation, is most often driven by the following 12 business motivations:

1. Efficiencies in communicating information between the office and the remote service technician or jobsite

2. Efficiencies in planning and scheduling work based upon location, parts and expertise needed

3. Reducing fuel costs

4. Reducing travel time

5. Reducing time consuming and error prone data entry activities in the office

6. Increasing productivity – more average service calls per service technician in a day

7. Increasing service contract sales

8. Increasing equipment upgrade sales

9. Increasing collections with mobile invoicing, mobile printing of invoices and onsite collections

10. Improving inventory control and management - visibility to parts needed, the location of inventory and parts used on each job or service ticket

11. Reduced risks by reminding service technicians of safety hazards and safety procedures on the job

12. Improving management visibility into work done in the field to ensure quality services

These 12 business motivations become increasingly important during slow economic times. In rapid growth periods inefficiencies are often overlooked in a rush to keep up with the market and business growth, and hidden under the onslaught of new sales and revenues. However, when the economy slows down, it is time for companies to re-evaluate business processes in order to eliminate the inefficiencies and bad habits that have developed. Let’s now review some common and costly inefficiencies:

1. Inefficiency # 1 -Wasted time and fuel driving back and forth to the office to pick-up and deliver new work orders, tools and parts. With the high cost of fuel, reducing driving distances is a necessity. Can you dispatch a service technician directly from their home to a nearby jobsite? Can you make sure your service technician has the most common parts in the van before they travel to the jobsite?

2. Inefficiency #2 – Wasting time and fuel by being unprepared for the job and driving around looking for parts. Can you reduce travel time and fuel costs by being better prepared for the job before traveling? Can you ask customers for more information on the equipment such as brand, serial number, year, location, problem etc? Can you ask the customer for a digital photo of the equipment, serial number, etc., and email it before dispatching the service technician?

3. Inefficiency #3 – Sitting outside of a locked and vacant location wasting time waiting for the owner to arrive. Can you set up an automated phone call to let the customer know you are on the way? This avoids showing up at a vacant house or closed business and wasting time.

4. Inefficiency # 4 – Sending service technicians to a distant location, when another service technician is closer and wasting time and fuel. Can you use GPS tracking on the vans to better know the location of all service technicians so you can dispatch the closest and best service technician for the job?

5. Inefficiency #5 – Missed opportunities to sell more services, parts and equipment to the customer at the time of work. Can you automatically remind the service technician to promote service contracts by using a mobile handheld work order system? This will help increase service contract sales.

6. Inefficiency #6 – Poor scheduling and routing. Can you schedule service contract visits based on geographic location to reduce fuel costs and wasted travel time? Can a service technician complete more service calls in a day if they are routed more efficiently?

7. Inefficiency #7 – Driving large and heavy vehicles when not required. If you have a better understanding of the parts required for today’s service calls, can you take a smaller, more fuel efficient vehicle to the jobsite?

8. Inefficiency #8 – Poor cash management and collect processes. Can you collect money, swipe credit cards and print receipts from a mobile handheld device to improve collections at the jobsite? Are you wasting time, paper and postage sending out invoices weeks after the work was completed?

9. Inefficiency #9 – Too much administrative costs. Can you reduce the costs of data entry and administrative staff by automating the dispatch process by using wireless work order dispatch that is integrated directly with your work order management and accounting systems?

Every company, upon self-evaluation, will be able to identify additional inefficiencies that can be corrected and reduced. Many of the costly inefficiencies can be resolved by automating and mobilizing field services business processes.

What does an automated and "mobilized" work order system or service request dispatch and management system look like? A customer calls in to report a broken heating system. The office staff takes the phone call, enters the relevant information into the work order application on the desktop computer which then creates a unique work order and number.

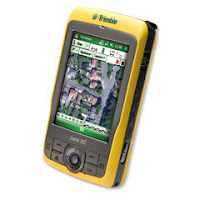

The work order database application, with GIS integration, can compare the location of each service technician to determine which service technician is closest to the work location. The dispatch system can also look at the estimated time the nearby service technicians are committed to completing their existing assignments. Once the appropriate service technician is identified, the work order is dispatched to the handheld computer used by the service technician. Included in the electronic work order is driving directions from his/her current location to the next job location. In addition to the work order information, warranty, repair, users manual, maintenance history and product information on file can also be dispatched to the handheld computer for reference and parts inventory management.

Once the service technician arrives at the location, he opens the work order on the handheld computer. Opening the work order automatically captures the service technician's name, the date/time stamp and the GPS coordinates of the jobsite and enters them into the mobile application’s work order.

Next the service technician examines the broken heating system and determines which parts need replaced. He can pull out his handheld computer and check whether he has the needed parts in his vehicle inventory, if not, it can automatically search for nearby service vehicles that may contain the part (GPS tracking enables this). If another nearby service vehicle is determined to have the required part, then driving directions can be sent.

When the service technician arrives at the service vehicle with the needed part, then the part is scanned using a bar code scanner in the handheld computer to log its removal from the vehicle's inventory and assigns it to the appropriate work order number.

Back at the work site, the service technician runs into a challenge. He has never worked on this model before and needs advice. He snaps a digital photo of the equipment and synchronizes it back to the office. His supervisor reviews the photo and calls him with advice.

Once the work is completed, the service technician signs his name on the handheld computer screen, and has the customer sign the work order screen as well. The service technician prints an invoice on a mobile printer and collects the payment or swipes the customer’s credit or debit card. The collection is noted on the mobile work order and synchronized back to the office.

As soon as the work order is completed and synchronized, the mobile application reminds the service technician to promote a 2 year service contract. The service technician reviews the details with the customer and signs them up for a 2 year service contract. Next, the work order system reviews job locations and priorities and assigns the next optimized work order to the field service technician.