Kevin Benedict is a TCS futurist and lecturer focused on the signals and foresight that emerge as society, geopolitics, economies, science, technology, environment, and philosophy converge.

Digital Thermometers, Restaurants & Handheld PDAs

I wonder if the medical field would like this feature?

An additional requirement was for service technicians installing and maintaining equipment in these restaurants to be able to take "before and after" digital photographs to document their work. I know Plastic Surgeons would like this feature. This was important because the restaurant owners did not live in the same region as these restaurants and wanted to view the completed work before paying for it.

Military Use of PDAs & Monitoring Grass Clippings

Our application was mission critical only to the groundskeepers on the US Airforce base in Germany. Seems they needed to inspect hedges, lawns, sprinkler systems, third party landscape contractors, flower beds and the removal of grass clippings.

OK, not as exciting as I had hoped, but valuable none the less. Their current method of tracking the quality and work to be done on the landscape of this very large military base was to document everything on paper forms. This data would then be entered into a database application in the office to manage the work and dispatch landscape maintenance crews. By automating this process using electronic forms on PDAs that synchronized with their database application, they were able to make this process much more efficient.

Oprah will have to wait.

PDAs and Inspections

I have spent a lot of time with government agencies this month reviewing how they monitor and inspect an organizations' compliance to various laws and regulations. For example, today we delivered a solution to a government agency called the Board of Pharmacy. They will be monitoring and inspecting facilities to ensure they are handling and storing medical drugs in compliance with the laws and regulations of their state.

Last month we supplied PDA based inspection forms to the City of Amsterdam in Holland. They are inspecting and monitoring compliance with environmental laws and regulations.

We are now starting our 3rd mobility software project with the Idaho Transportation Department. They inspect their facilities and the work third party contractors do for them. This data is synchronized to a central database from all across the state. Our latest project involves enabling mobile printing from their Pocket PCs in the field.

When government agencies contact us about inspection solutions on PDAs the conversations usually go like this:

Agency: Is there a way we can fill out an inspection form on a PDA that can then be synchronized with our office databases without needing to re-type the data again once we return to the office?

Kevin: Yes

Agency: Can I look up, on my PDA, my past inspections at this location to see if they were non-compliant with any items on previous inspections?

Kevin: Yes

Agency: Can I reference the definitions of various terms on my inspection form to better understand how to grade or rate a particular item?

Kevin: Yes

Agency: Can I make a "smart inspection form" that will route me to a different sets of questions based upon the data I enter on my inspection form?

Kevin: Yes

Agency: Can I print the results of my inspection and leave a copy at the premises?

Kevin: Yes, if you have bluetooth enable PDAs and bluetooth enabled printers. You can print on 2", 3" 4" or regular A4 or 8 1/2" x 11" paper.

Agency: Once I have your software for quickly creating inspection forms that synchronize with my enterprise database, can I edit my own inspection forms?

Kevin: Yes, we provide you with the software development kit for creating and editing inspection forms.

Agency: Is a PDA based inspection solution expensive?

Kevin: No

Agency: Does your company know you are blogging and other people can read this?

Kevin: ...not yet

PDA Phones with Integrated GPS

Once you have integrated GPS with your "work order management system" you can add GIS and geospatial data collection to your application. Basically what this means is you can associate your work, orders, deliveries, inspections, etc. to a GPS coordinant. Once again this will help management understand patterns, costs, best routing methodologies, locations to build new facilities, and much more.

PDAs in Angola, South Africa, New Mexico, Germany, Portuguese & Kwanza

- German citizen

- Living in South Africa

- Owns a bottled water business in Angola

- Has a home in New Mexico, USA

- The handheld computer applications must be written in Portuguese & English

- The currency must be in US Dollars & Angolan Kwanza

- Solution requires a bar code scanner and mobile printers

- A Ruggedized handheld computer

- Must be as graphical as possible (many of the users can not read)

- Synchronization using satellite internet connections

It has been our strategy since 2000 to develop “software development kits” for mobile environments. Because of the power and flexibility of the "software development kit" approach, we can easily develop and implement cost effective projects with the above described unusual requirements.

What Part of Your Application Do You Mobilize?

- How does your mobile workforce capture data today? Do they use paper forms and a clipboard?

- Where is the primary ROI (return on investment) coming from? Is it eliminating data entry at the office? Is it extending business processes to the mobile workforce? Is it getting complete and valid data from the field? Is it the ability to query enterprise information from the field? Is it visibility to real-time data (inventory, shipping, project status, etc.)?

- Do you need your entire enterprise database application in the hands of your mobile workforce, or only a subset?

- Do you require a full laptop or Tablet PC, or can you accomplish your goals with handheld PDAs?

The answers to these questions helped us understand what to mobilize first. Handheld PDAs do not yet have the same level of data storage and memory that are available on enterprise database servers. Therefore, you need to determine what subset of data and software functionality you need on the handheld PDA to get your desired ROI.

If the primary reason for mobilizing your "service orders" is to eliminate the need to re-type all of the information once you return to the office, then electronic forms with database synchronization is enough. If you want your mobile PDA application to be pre-populated with data from your enterprise database, then this is another level of sophistication. If you want your PDA application to take advantage of handheld computer components like GPS, digital cameras, Bar code scanners, GPRS data cards, etc., then you can add this layer. If you want lots of validations and business logic on the handheld this is another consideration.

The bottom-line, find your primary source of ROI, and start there with version 1 of your mobile application. You can then prove to yourself the value of mobilizing your business processes and then confidently build from there.

Handheld PDAs & Mobile Home Healthcare Services

MobileDataforce was founded as the result of several mobility projects on Palm OS devices in year 2000. We started as the IT department for a company providing community based assisted living care to mentally disabled adults. The Department of Health and Welfare support the care of many of these individuals and all of the services must be completely documented and regularly audited.

The volume of paper forms that are required and the challenges with managing care state wide motivated our founders to seek ways to use electronic forms on PDAs to capture data and synchronize it with a central database.

The first step was to convert paper forms into electronic forms that could be used on PDAs. After successfully creating a few of these electronic forms with a lot of time and effort, we realized it would be more efficient to create a software development tool set to speed it up. This development tool set became Intercue Mobility Suite. Our founders used Intercue Mobility Suite to automate their Quality Assurance forms, Timesheets, Initial Assessment forms, and many other paper processes. These forms can now be filled out on PDAs around the state and synchronized with a central database.

We started with Palm OS support only in 2000, but quickly added Pocket PC, Tablet PC, Windows XP and now Win CE.Net.

The Intercue Mobility Suite was first available to the public as a product in 2003. It is now used around the world for remote data collection and database synchronization. In 2005 a database centric software development environment was released by MobileDataforce called PointSync.

Synchronizing PDA Applications Remotely

- Synchronize using your GPRS mobile phone network with your PDA Phone, or ruggedized handheld computer using a data card.

- Synchronize using a traditional dial-up connection on your phone. You can get modem cards for your PDA or ruggedized handheld computer.

- Wait and synchronize when you return to the office or your home computer with internet connection.

- Synchronize using WiFi, this is not common in Remote-Mountains, Idaho, but Boise and beyond all have this.

- Synchronize using a bluetooth connection to a laptop database. If you have a large database on your laptop, and want to synchronize some of the data to the handheld, but not all, you can configure the appropriate data to be synchronized from the laptop to the PDA or ruggedized handheld for use in the field where the laptop is not appropriate (climbing trees, exploring caves, hopping fences, wading in swamp lands, etc.)

The bottom line is that you can synchronize to a central database from any place where you have access to an internet connection.

Field Services, Work Orders & PDAs

Work Orders on handheld PDAs are the most common requests from companies contacting us. Why? Traditionally field service technicians use paper forms and a clipboard to document their work. Once the field service technician returns to the office they deposit these completed (hopefully completed) work orders in a stack to be entered into a computer system at a later time. Immediately we recognize a problem in that 2 people are required to enter the data, not just 1. Here are a list of additional costs with a paper process:

- Incomplete work orders that require the data entry person to track down the field service technician for additional information.

- Unreadable handwriting that requires translation by the field service technician

- Delayed response time when additional parts need ordered to complete the work

- Delayed re-scheduling when return visits are required

- Lack of visibility to part's inventory

- Lack of visibility to other field service technicians' schedules

- Lack of effective route planning

Many of these inefficiencies involve the field service technician calling the office, and using the office staff as an intermediary to gather information. This process turns a 1 person task into a 2 or 3 person task. Automating the "work order" process can save a great deal of time and money.

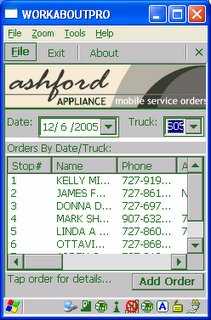

We often configure mobile work order management applications on a handheld PDA to do the following:

- Show a list of all assigned work orders for a field service technician

- Enable the field service technician to open and close work orders on the PDA

- Synchronize work orders directly to the work order management system in the office

- Send new work orders directly to the PDA in the field

- Integrate GPS with the work order management application so the office has visibility to the location of the field service technician.

- Enable the printing of work orders with digital signatures at the customer's location

- Check inventory levels via the PDA with a wireless connection to the office inventory software.

- Order parts from the field service technician's handheld to expedite the process

- Reschedule appointments from the field

New technologies in 2006 will also enable the field service technician to talk through their handheld PDAs directly with the dispatch center. Many handheld computer manufacturers are adding this VoIP technology now.

It is very easy to demonstrate a positive ROI with Mobile Work Orders. We have an ROI calculator on the bottom of our website that you can use to determine your specific ROI.

Pocket PC Solutions for Waste Management

The European Community has passed a series of laws regulating the handling and disposal of waste and recyclable materials. I also read in the newspaper last week that the state of Maine has recently passed similar laws. Waste producers must have an audit trail or documented "chain of custody" of their waste from origin to disposal. They must maintain records of the amount, and type of waste, when it was picked up by a trucking company and delivered to a collection facility, and ultimately delivered to the final disposal company. This audit trail involves a lot of paper and must be available for access by government agencies that audit this process.

The waste collecting trucking companies need to collect data at the site of the waste pick-up, and they have been seeking a good solution to this paper headache.

The solution involves handheld PDAs using MobileDataforce's PointSync that are integrated to a Waste Management applications in the office. This Waste Management application is often web enabled to allow the waste producer to view their "pick-up reports" for auditing purposes in near real-time.

The value of this applications goes beyond just data collection efficiencies provided to the waste collecting trucking companies. The value is in keeping an electronic chain of custody record that is accessible to all participants in near real time.

Route Delivery - PDAs & Handheld Computers

My team is just wrapping up the implementation of an interesting project that involves route sales and delivery. This project involves the usual features on their PDA software such as:

- Delivery person login/password, time/date stamp

- Store look-up query

- Review of store inventory data

- Product delivery update

- Inventory update

- Sign-off

The unique part of this software application developed in PointSync is the "planogram". This PointSync micro-application predicts how much product the specific store usually requires between deliveries. For example - store 104 averages 6 boxes of widgets number 97 between deliveries. The delivery driver/sales person does not have to determine the appropriate number, the application predicts it based upon historic data in the database on the handheld computer.

This kind of application is interesting because rather than simply displaying data, it uses this data to "think" on behalf of the user and to provide instructions to the user. This is true business process automation at work on a PDA.

New PDA Website

PDAs, Elk, RFID & Geospatial Data Collection

In Idaho people farm elk, not all people, some farm potatoes. These elk farmers need to protect their herds against disease, and document the fact that their herds are disease free. These farmers must register the locations of their herds using GPS coordinates, and then collect geospatial data concerning the details of the herd, their immunizations, history, etc. This is becoming increasingly important, since if one herd has a disease, it could impact the sales of all meat in that region. Farmers must not only protect their animals, but effectively market and promote the health status of their herd in order to continue selling during times of disease.

It is not enough to document the location and health of your herd, one must document the location and health of each individual animal. RFID ear tags are often a good solution to this. In my discussions last week concerning the elk farmers, these farmers created collection zones where all animals walk through a specific location, whether a water trough, feedlot, or salt lick. These locations funnel the animals through narrow paths where RFID readers can collect and inventory the details of the herds and individual animals. This information allows these large animals to be effectively managed and documented without trauma and risk of injuring the animals through large round-ups and corral lock-ups. Elk are strong, wild and flighty and it is dangerous to handle them. Therefore, the less you need to confine and handle them, the better.

PDAs are used through-out this process to document information on herds, pastures, health, births, injuries, deaths, GPS coordinates and much more. MobileDataforce's PointSync solution can effectively be used to develop and customize these mobile applications.

PDAs in the Automotive Industry

- Marketing and consumer input - PDAs are being used to gather consumer feedback and information after a person test drives a new car

- Automobile Inspections - PDAs are being used to automate the process of inspecting automobiles at auctions

- Work Orders, Part 1 - detailers at automobile dealerships are tracking work completed on PDAs

- Work Orders, Part 2 - third party mobile auto body shops are using PDAs to track windshield repair, dent removal, spot painting, and headlight repair on used cars. The PDA based work orders are used to document work and to invoice for the work.

- Banking in the Automotive Industry - PDAs are being used by banks to verify automobile inventory at a dealership

- Location based applications - PDAs with RFID readers are being used to identify the location of a specific car in a large lot. Some of these are using a triangulation of long range RFID signals.

- Industrial trucks - RFID applications are being used to track all portable equipment in the back of service trucks. Items such as ladders, generators, tools, etc. are each given an RFID tag. If the service truck drives away from the tools, the RFID signals will be lost and a warning is sent to the driver's PDA that identifies the tools left behind. This requires an RFID reader in the service truck, and tags on all appropriate tools.

These are all very interesting projects that have come across our desks recently. It is amazing how many business processes can benefit from the use of appropriate mobile technology in the field.

Fleet Management - Handhelds and Satellites

Yesterday Wireless Matrix and Psion Teklogix published press releases concerning a project they both did using MobileDataforce's PointSync that involved some interesting technology in the transportation of rail crews. Here is an excerpt:

The new rugged system enables RailCrewXpress to record the location and transportation activity of the company's vehicle fleet in real-time. RailCrewXpress handles the majority of the U.S. Class 1 railway crew transportation needs, including crew pick ups, transport to trains, shuttling crew to hotels for overnight stays and in-yard crew transport. With its new mobile computing solution, RailCrewXpress has complete visibility into the cargo and location of its fleet at all times.

This was a fun project that my team delivered. It involved a combination of GPRS and Satellite uplink technologies and our PointSync software solution on Psion Teklogix handheld computers mounted to the dashboard of the vehicles. When a vehicle in the fleet could not communicate using GPRS(mobile phone communication) then it would roll over to a satellite uplink. When using the satellite uplink, a different kind of synchronization is initiated that sends a smaller data set. Lot's of fun and pushing the envelope.

PointSync 3.0 Released

My engineering team has put over 12 man years into PointSync 3.0, and they are both thrilled and relieved to have it finished. I think we should give them the afternoon off before we start on version 4.0. In all seriousness, our engineers deserve a big congratulations! MobileDataforce's successes are the result of their amazing skills.

I am going to advertise a bit. PointSync is the culmination of all that we have learned about mobile software development tools since 2000. We wanted a comprehensive rapid application development environment that gives both novices and coders the ability to develop powerful end-to-end turnkey mobile solutions and PointSync accomplishes that.

You can download the PointSync Developer, and sample PointSync applications to view on your handheld computer. Let me know your thoughts!

Business PDA users a 'dream segment' for mobile operators

Business PDA users a 'dream segment' for mobile operators

The latest Wireless Enterprise Strategies service report from Strategy Analytics, "Profiling the PDA User: Strategies for Generating Network Traffic," affirms that business PDA users represent a prime segment which mobile operators and OEMs should actively identify and target for wireless solution sales. Device set-up, email synchronization and content creation must be dramatically reengineered.Cliff Raskind, Director of the Wireless Enterprise Strategies service commented, "When mobile operators survey their base of business customers, PDA users potentially represent a `dream segment' of users that is tailor-made for upselling many wireless data solutions enabled by next generation networks. While over half of the PDA users remain unconnected beyond simple text messaging, operators, device OEMs and solutions providers have failed to bridge a number of critical performance deficits relating to set-up and ease of use." David Kerr, Vice President of the Global Wireless Practice, noted, "PDA users spend more on mobility, experience much greater frustration when disconnected. They report strong interest in a basket of value added services. So far, however, a combination of device-centric and network-resident barriers have conspired to suppress attachment rates beyond the initial corner office inbox junkies. While improved data economics coupled with expanding device portfolios from Microsoft Mobile partners, Symbian camp evangelists and aspiring Asian vendors all augur well for the future, no dominant paradigm has yet emerged to transition these PDA users into true converged device solutions customers." This report provides a snapshot of the potentially lucrative PDA segment, revealing why they should be in the crosshairs of all mobile operators and device OEMs wishing to succeed in the business market.Other key findings from the report include: · At 105 Euros per month, PDA users spend 53 percent more than non-PDA users on mobile services; · PDA users average 34 percent more minutes of use than non-PDA users; · PDA users are better educated and more likely to buy premium products; · PDA users require more frequent access to email, CRM and other network-based applications.

PDAs and Engineers

- Phase 1 Site Assessments

- Nuclear Density Tests

- Soil samples

- Ground Water

- Concrete testing

- Many more

In addition to these field tests, often samples need to be documented and sent to a lab for analysis. This involves a "chain of custody". A chain of custody is when a sample is collected by a field technician, labeled and sent to a lab. The lab needs to document their receipt of the sample, analyze it, and report the results back to the engineering firm which passes this information back to their client. This process involves a chain of participants that all need to document their relationship to the test sample and test results from beginning to end.

This brief explanation of a simple process, identifies the necessity for documentation. Since the process starts in the field, it is appropriate to begin thinking about how data collection in the field could be automated. This is where handheld PDAs come in.

PDAs with customized engineering software can do the following:

- Capture GPS readings of the job site and the test site

- Digital signature of the person collecting the test data and samples

- Date, Time of test

- Identification of the client and project this test is billed to

- Weather conditions at the time of the test

- Physical description of the job and test site

- Documentation of the test performed

This information can all be documented on the PDA and wirelessly synchronized to the office database from the field. This saves both the engineer and the administration staff the work of re-typing the data again in the office.

Enterprise Mobility Framework

- 7 different synchronization methodologies

- 7 different mobile data security architectures

- 7 different ways of customizing mobile applications

- 7 different integration methodologies

- 7 different applications with different handheld computer support

- 7 different technical support centers

- 7 dfferent mobile software application vendors

The request they brought to my sales team was, "Can MobileDataforce help us develop a standardized mobility framework that can integrate 7 different enterprise applications with 1 mobile enterprise framework?" They wanted to purchase 1 solution that could provide all their requirements, which would save them a great deal of time, money and headaches.

That is exactly what my engineering team has been developing since 2000. The result is the new PointSync 3.0.

Handheld Inspections at Government Agencies

Here are some of the inspections identified:

- Boxed and shipped fresh produce

- Sugar content of produce

- Ground water quality

- Registered cattle pastures

- Certified immunization of cattle

- RFID cattle tracking

- Inspecting and certifying fertilizers

- Dairy farm inspections

- Dairy processing plant inspections

- Nitrogen levels on fields

- Insect and pest control

- much more....

The list was enormous and I was impressed with how mobilizing these inspections could save this government agency a considerable amount of money. I've got some work to do!

Mobilizing Facilities Management and CMMS

- Inventory

- Work Orders/service orders

- Preventative maintenance orders

- CMMS - computerized maintenance management systems - custodial/janitorial services

- Hazardous material tracking

- Server room management

- Inspections of all kinds

- Asset Management

- Health & Safety inspections

- Contractor Quality Assurance

- Moving instructions and details

- Office leasing information

- Fire extinguisher and emergency medical equipment inspections

- Much more...

FM professionals often are responsible for the operations of large buildings, campuses, warehouses, and remote properties. Their work consists of gathering all kinds of data from remote areas and entering this data into a central database where it can be managed by any number of FM software applications.

The challenge is not so much managing the data once it is in their FM software application, it is collecting the data and getting in entered into the FM software. This is where MobileDataforce comes in. Our software solutions for PDAs and handheld computers enable you to quickly create electronic forms and mobile applications that can be used in the field to collect data and then synchronize it directly into the FM software application. Our integration technology makes it a relatively simple process to integrate with most FM software applications.

Remote data collection is a big need, but also the ability to look up information on a building, maintenance project, business process or piece of equipment while you are inspecting the facilities. This requires your handheld PDA to have a RDBMS (relational database management system) on your PDA. Our PointSync solution enables you to replicate your FM application database on your handheld, so you can query information, and update information in the field. Any changes that you make in the field, will be updated to your FM application upon synchronization.

Adding Value to Your PDA

- Replace paper forms that you use in the field, with electronic forms on your PDA. These can be automatically synchronized with your back-office database applications.

- Load your product catalogs to your handheld PDA with price and product attributes

- Load work order/service orders onto your PDA so you can fill them out and synchronize remotely.

- Develop an inventory update application so you can check inventory levels and update them from the field.

- If you are an inspector, or dabble in filling out inspection forms, create electronic versions that automatically load to your database or spreadsheet.

- Add a bar code scanner to your PDA so you can scan product barcodes and see inventory levels.

- Add GPS to your PDA so you can quickly find your next job site or customer location.

- Are you filling out time sheets in the field? If you are a supervisor, you can enter the timesheets of your entire crew and synchronize this information to your office remotely.

- Do you need to compute a lot of numbers in the field? Do the results of these numbers change what you should be doing in the field? Create a mobile application that can compute your input data and direct your actions based upon results. We work with a lot of inspection processes where the result of the inspect impacts the next step in the business process.

- Print forms while in the field. Once your electronic form or mobile database application in your PDA has data in it, you can print it to a mobile printer. You can look up historic information and print this for your customers as well.

- Quality Assurance forms - we have a lot of large companies that send out Quality Assurance auditors to inspect their facilities and processes. You can easily replace these paper processes with mobile applications on your PDA. The value? Quick input of field data so you can immediate analyze the data and implement Q&A improvements.

This list identifies a few of the most common uses for PDAs in the field. All of these applications add value to your PDAs and handheld computers.

MobileDataforce, http://www.mobiledataforce.com provides software solutions for quickly and affordably developing and implementing these kinds of solutions.

Implementing Mobile Projects

Here are some sample questions:

- What handheld hardware will you be using(make and model)?

- What add-on accessories will you be using (GPS, RFID, Digital Imager, Barcode, etc)?

- Where and how will the user be synchronizing their handheld(at home, office, shop, WiFi, GPRS, cradle, bluetooth, Satellite)?

- What operating system does your handheld computer have (Win CE.Net, Pocket PC, Palm)?

- Do the users have working conditions that will impact our solution design (users wear gloves and need big touch screen buttons)?

- What business process will be mobilized (work order, invoice, time sheet, project status, etc.)?

- What database do we need to connect to? How do we access it? Can you provide a data model?

- Do you need mobile printing?

- Do you need formatted reports? Will they be printed in the field, or in the office?

- Do you need internet access to this data? If so, who will design the website?

- Are you going to conduct a "proof-of-concept" first? If so, how many users? What is included in the POC. How do we measure success?

- Concerning roll-outs - how are we going to roll out this solution to your billion mobile users? How many at a time?

- How are you going to train the users?

- When are you going to have the handheld computers delivered?

- Who will install the software and document how to use them in the field?

These are a few of the questions that an experienced team of consultants and systems integrators will ask you before they provide you with a quote. If a consultant does not ask these questions upfront, it does not mean they are bad, just inexperienced and will likely not meet their timelines and cost projections.

Paper Forms or Electronic Forms on PDAs?

What is the downside to using a paper form with a clipboard?

- Paper forms are often submitted with missing information. This lack of completeness wastes considerable time in the office as staff try to contact the original author and gather the missing data.

- Paper forms can often be left on the clipboard for days or weeks, so there is a delay in getting the information transferred from the paper form into a computer software application for processing.

- Handwriting on the paper forms is often hard to interpret. This allows for bad data entry into the computer system. Bad data in - bad data out.

- Paper forms can not validate the information entered on them. So invalid information can be written on the paper forms.

- Paper forms are easily misplaced, lost or damaged by environmental factors and irresponsibility.

- Paper forms can not effectively provide you with a list of all possible correct answers. Electronic forms can provide you with "pick lists" or "drop down" menus that limit your answers to only valid ones.

- Paper forms do not provide you with the ability to query all "products" in a catalog. Electronic forms that are tied to a database on your handheld PDA, can enable you to "look-up" lists and databases with product listings and product attributes that will automatically fill in the electronic form.

- Paper forms do not compute. Electronic forms can compute math, invoice totals, elasped time on a projects, milage, square feet, and much more.

- Paper forms can not link to many other applications that can provide GPS coordinates, RFID reading, bar code scanning, digital images, CAD drawings, etc.

The above list identifies some of the deficiencies of a paper form, however, there are times when either a paper form or a full sized laptop is simply more efficient. I find that when there are a great deal of notes to be taken, it is not efficient to attempt this on the limited screens that PDAs provide. If you have 3 pages of observations and notes to be entered, you need to either handwrite on paper, or use a full sized keyboard connected to a laptop or desktop. Another case is when you have large maps or CAD drawings to view. A PDA screen can be used for specific views, but PDAs are not practical for viewing large areas. In this case either a laptop, Tablet PC or paper version is more efficient and saves your eyes.

Working with a Budget, Part 4

- Someone needs to develop the "mobile client" software that synchronizes with your Work Order Management software in the office. Is this going to be your cousin Bob, or a professional IT developer or consultant? If you are going to use a professional, get a quote on the project costs.

- Are you going to develop your own mobile software from scratch, or purchase a "software development kit" for mobile solutions from a company like MobileDataforce, http://www.mobiledataforce.com? Get a quote from the software vendor.

- Are you going to buy a $300 consumer grade PDA that can be easily broken when dropped, or are you going to spend $1,500 on a water resistant and dust resistant handheld that can be dropped to concrete from 6 feet. Search on ruggedized handhelds or call MobileDataforce for referrals.

- Do you want to call your field service technicians on their mobile phones and read them their next work order, or do you want to have it synchronized out to their handheld device in the field? Contact your wireless service provider for data connection quotes using PDAs or handheld computers with data cards.

Once you have made up your mind about these various issues and received quotes, it is time to set project schedules, implementation and test plans.

Interviews with Kevin Benedict

-

Futurist David Espindola’s new book has just been released, "Soulful: You in the Future of Artificial Intelligence." Alex Whittin...

-

I had a great time participating in the filming and development of a 10 minute film on digital twins recently. Last week was its premier at...

-

In this deep dive with Munich Re (Groups) cybersecurity expert Bob Parisi, we learn how the insurance and reinsurance industry develops poli...